E-commerce Shipping & Fulfillment: Cut Costs & Improve Delivery in 2025

Optimizing e-commerce shipping and fulfillment in 2025 goes beyond logistics; it involves strategic technology integration and customer-centric approaches to significantly reduce costs and enhance delivery times.

In the dynamic world of online retail, customer expectations for speed and affordability in delivery are constantly rising. For businesses striving to thrive in this competitive landscape, mastering e-commerce shipping and fulfillment: cut costs and improve delivery times in 2025 is not merely an operational task but a strategic imperative. This guide delves into actionable insights and innovative strategies to revolutionize your logistics, ensuring efficiency and customer satisfaction.

The Evolution of E-commerce Fulfillment: A 2025 Perspective

The landscape of e-commerce fulfillment is undergoing a profound transformation. What was once a simple process of picking, packing, and shipping has evolved into a complex ecosystem driven by technology, customer demands, and global supply chain shifts. Understanding this evolution is crucial for any business aiming to optimize its operations in 2025.

Gone are the days when a general shipping solution sufficed. Today, consumers demand rapid delivery, often expecting same-day or next-day service, alongside transparent tracking and flexible delivery options. This shift places immense pressure on e-commerce businesses to refine their fulfillment strategies to meet these heightened expectations without escalating costs unsustainably.

Key Drivers of Change in 2025

Several factors are shaping the future of e-commerce shipping and fulfillment. Acknowledging these drivers allows businesses to proactively adapt and innovate, rather than merely reacting to market shifts. The focus has moved towards predictive analytics, personalized delivery, and sustainable practices.

- Speed and Convenience: Consumer desire for instant gratification continues to push delivery speed boundaries.

- Technological Advancements: AI, robotics, and IoT are redefining warehouse operations and logistics.

- Sustainability Concerns: Growing pressure from consumers and regulators for eco-friendly shipping practices.

- Global Supply Chain Volatility: The need for resilient and agile supply chains to mitigate disruptions.

Embracing these changes isn’t just about survival; it’s about gaining a distinct competitive advantage. Businesses that can flexibly adapt their fulfillment models will be better positioned to scale and capture market share.

Strategic Cost Reduction in E-commerce Shipping

Reducing shipping costs is a continuous challenge for e-commerce businesses, especially as freight charges and last-mile delivery expenses continue to rise. However, there are numerous strategies that, when implemented smartly, can significantly lower your operational expenses without compromising service quality.

The first step often involves a comprehensive audit of current shipping processes. This audit can reveal hidden inefficiencies, unnecessary expenditures, and opportunities for consolidation. It’s about scrutinizing every step from packaging to carrier selection.

Optimizing Packaging and Weight

One of the most immediate ways to cut shipping costs is by optimizing packaging. Lighter, more compact packages translate directly into lower shipping fees, particularly for carriers that use dimensional weight pricing. This strategy requires a careful balance between protection and cost-efficiency.

Consider the impact of packaging on dimensional weight, which calculates shipping cost based on the package’s volume, not just its actual weight. This means even lightweight items shipped in oversized boxes can incur high costs.

- Minimize Void Fill: Use only necessary void fill to prevent movement and damage.

- Right-size Packaging: Choose boxes and mailers that are appropriately sized for the product.

- Lightweight Materials: Opt for lighter, yet durable, packaging materials.

- Custom Packaging: Invest in custom boxes that snuggly fit your most popular products.

These seemingly small changes can accumulate into substantial savings over time, especially for high-volume shippers. Reevaluating packaging processes should be an ongoing task, aligning with new product launches and packaging material innovations.

Negotiating Carrier Rates and Diversifying Options

Relying on a single shipping carrier can limit your leverage and flexibility. Engaging in direct negotiations with multiple carriers and diversifying your shipping partnerships can unlock better rates and more suitable services for different package types and destinations.

Don’t assume published rates are fixed. Carriers are often willing to negotiate volume-based discounts, especially if you can commit to a certain level of business. This requires a clear understanding of your shipping volume and patterns.

Exploring regional carriers or specialized freight companies for specific types of shipments can also yield significant savings. These niche providers often offer more competitive rates and tailored services than national giants for certain routes or package dimensions. A robust carrier diversification strategy ensures that you are not solely dependent on one provider, providing a safety net against disruptions and price increases.

Enhancing Delivery Times and Speed

In the “now economy,” fast delivery is a non-negotiable expectation for e-commerce customers. Improving delivery times not only boosts customer satisfaction but also reduces cart abandonment rates and enhances brand loyalty. Achieving faster delivery, however, requires a multi-faceted approach involving technology, strategic warehousing, and efficient last-mile logistics.

Leveraging Distributed Inventory and Micro-Fulfillment Centers

One of the most effective ways to cut down on delivery times is to reduce the distance between your products and your customers. This involves strategic placement of inventory closer to major demand centers, often through distributed fulfillment networks or micro-fulfillment centers (MFCs).

MFCs, typically smaller, automated facilities located in urban areas, enable ultra-fast delivery by positioning inventory within miles of the end consumer. This model is particularly effective for same-day or next-day delivery promises, reducing transit times dramatically.

- Reduced Transit Times: Shorter distances mean packages reach customers faster.

- Lower Last-Mile Costs: Proximity can reduce fuel consumption and labor costs for delivery.

- Improved Customer Satisfaction: Meeting and exceeding delivery expectations.

- Increased Market Reach: Ability to offer competitive delivery speeds in new areas.

Implementing a distributed inventory strategy requires careful analysis of customer demographics, popular product locations, and transportation networks. It’s a significant investment but one that frequently pays off through increased sales and customer retention.

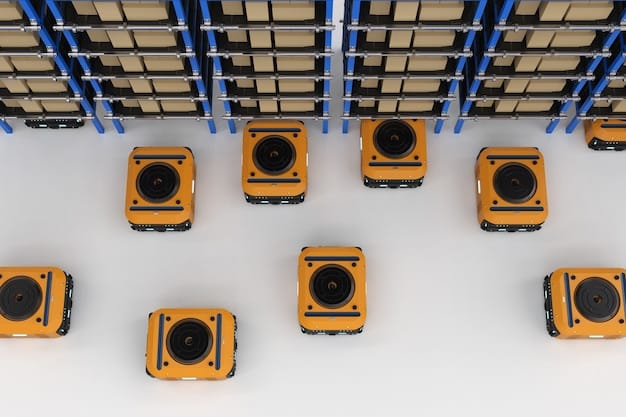

Automating Warehouse Operations

Automation within the warehouse or fulfillment center is no longer a luxury but a necessity for speed and accuracy. From robotic picking systems to automated sorting and packing machinery, technology can significantly accelerate the fulfillment process from order reception to package dispatch.

The gains from automation extend beyond speed; they also include accuracy improvements, reduced labor costs, and better inventory management. Automated systems minimize human error, ensuring that the right product is picked, packed, and shipped every time.

Investing in warehouse management systems (WMS) that integrate with other e-commerce platforms is crucial. A sophisticated WMS can optimize pick paths, manage inventory levels in real-time, and streamline outgoing shipments, all contributing to faster processing times. These systems provide critical data insights that can further inform process improvements and resource allocation.

Technology Integration for Seamless Fulfillment

The backbone of efficient and cost-effective e-commerce shipping in 2025 is robust technology integration. Siloed systems lead to inefficiencies, errors, and delays. A connected ecosystem, from order placement to final delivery, is paramount for scalability and competitiveness. The goal is to create a seamless flow of information that drives smart decisions and automated actions.

Implementing advanced Order Management Systems (OMS)

An advanced OMS acts as the central nervous system for all order-related processes. It manages orders from various sales channels, connects with inventory systems, communicates with fulfillment centers, and updates customers on their order status. A sophisticated OMS minimizes manual data entry and reduces the likelihood of fulfillment errors.

Key functionalities of a modern OMS include real-time inventory visibility across all locations, intelligent order routing to the closest fulfillment center, and integration with shipping carriers. This level of orchestration ensures that orders are processed as efficiently as possible, reducing both time and cost.

Furthermore, an effective OMS can handle complex scenarios like split shipments, backorders, and returns with ease, providing a consistent and positive customer experience. Its ability to provide a single source of truth for all order data is invaluable for streamlined operations.

Utilizing Predictive Analytics and AI in Logistics

Predictive analytics and artificial intelligence (AI) are transforming logistics by enabling businesses to anticipate demand, optimize routes, and proactively address potential disruptions. AI algorithms can analyze historical sales data, seasonal trends, and external factors (like weather patterns) to forecast demand with greater accuracy.

This foresight allows for smarter inventory stocking, preventing both overstocking (which ties up capital) and understocking (which leads to stockouts and lost sales). AI-driven routing optimization can dynamically adjust delivery routes in real-time, factoring in traffic, road closures, and delivery time windows, ensuring the fastest and most efficient possible delivery. For example, AI can analyze countless data points to recommend the optimal shipping method for a package, considering cost, speed, and reliability.

Moreover, AI can enhance customer service by powering chatbots that provide instant, accurate updates on package status, reducing the burden on customer support teams. This predictive capability translates directly into cost savings through optimization and improved customer satisfaction through reliability.

Optimizing Returns and Reverse Logistics

While often viewed as a cost center, an efficient returns management process (reverse logistics) can significantly impact overall customer satisfaction and even contribute to cost savings. A smooth returns process builds customer trust and reduces the operational burden of handling returned items.

E-commerce businesses must recognize that returns are an inevitable part of online retail. The goal isn’t to eliminate them entirely, but to manage them quickly, efficiently, and cost-effectively. A well-defined reverse logistics strategy can turn a potential negative customer experience into a positive one.

Streamlining the Returns Process

Making the returns process as easy as possible for customers is paramount. This includes clear return policies, readily available return labels, and multiple return options (e.g., mail-in, in-store drop-off). The smoother the customer experience, the less likely they are to become dissatisfied.

- Clear Return Policy: Easily accessible and understandable rules for returns.

- Automated Return Labels: Generate labels with a few clicks.

- Multiple Return Options: Offer flexibility to customers.

- Fast Refunds/Exchanges: Process returns quickly to maintain goodwill.

Internally, streamlining return receiving, inspection, and restocking processes is critical. Utilizing dedicated areas for returns and leveraging technology to automate data entry for returned items can significantly speed up processing times, allowing returned items to be re-entered into inventory or disposed of more quickly.

Leveraging Technology for Returns Management

Dedicated returns management software can automate many aspects of the reverse logistics process. These platforms can generate return authorizations, track returned items, integrate with inventory management systems, and even initiate refunds or exchanges automatically once an item is received and inspected.

Such technology provides valuable insights into return patterns, helping businesses identify common reasons for returns (e.g., sizing issues, product discrepancies). This data can then be used to address root causes, such as improving product descriptions, enhancing quality control, or refining sizing guides, ultimately reducing future return rates. By turning return data into actionable insights, businesses can improve their products and processes, creating a virtuous cycle of continuous improvement and cost reduction.

Sustainability in E-commerce Shipping

As consumer awareness and regulatory pressures grow, sustainability is no longer an optional add-on but an integral component of responsible e-commerce operations. Integrating sustainable practices into shipping and fulfillment not only benefits the environment but can also enhance brand reputation and appeal to environmentally conscious customers.

The journey towards sustainable shipping involves a reevaluation of materials, transportation methods, and operational footprints. It’s about finding ways to reduce environmental impact without sacrificing efficiency or affordability. This often requires innovation and collaboration with eco-conscious partners.

Eco-Friendly Packaging Choices

One of the most visible aspects of sustainable shipping is packaging. Moving away from single-use plastics and non-recyclable materials in favor of options that are recyclable, biodegradable, or made from recycled content can significantly reduce your environmental footprint.

This includes using biodegradable packing peanuts, recycled cardboard boxes, paper tape, and even reusable packaging solutions where feasible. Communicating these efforts to your customers can also serve as a powerful marketing message, aligning your brand with their values.

The transition to eco-friendly packaging might involve an initial investment or slight increase in material costs, but the long-term benefits in terms of brand loyalty and environmental stewardship often outweigh these considerations. Moreover, as sustainable materials become more mainstream, their costs are likely to decrease.

Carbon Offset Programs and Green Logistics

Beyond packaging, businesses can explore carbon offset programs to mitigate the environmental impact of their shipping activities. These programs allow companies to invest in projects that reduce greenhouse gas emissions elsewhere to compensate for their own emissions.

Furthermore, implementing green logistics practices involves optimizing transportation routes to minimize fuel consumption, consolidate shipments to reduce the number of trips, and exploring alternative fuel vehicles or electric delivery fleets. Partnering with carriers that prioritize sustainable practices and have strong environmental policies can also be a key step.

The commitment to green logistics demonstrates a strong corporate social responsibility, which resonates positively with a growing segment of consumers. It’s an investment in the planet that also pays dividends in consumer trust and brand image.

Future-Proofing Your Fulfillment Strategy

The e-commerce landscape is in a constant state of flux. To remain competitive and efficient, businesses must adopt a forward-thinking approach to their fulfillment strategies, anticipating future trends and building flexibility into their operations. This proactive stance ensures resilience against market shifts and emerging challenges.

Embracing AI and Machine Learning

Beyond predictive analytics, AI and machine learning will play an even more pervasive role in optimizing every aspect of fulfillment. From automated customer service to self-optimizing logistics networks and intelligent robotics, their integration will continue to drive unprecedented levels of efficiency and personalization. Investing in AI-driven tools now can provide a significant head start.

These technologies allow for dynamic adjustments to stock levels, real-time rerouting of deliveries based on unforeseen circumstances, and personalized delivery options based on individual customer preferences. The ability to learn and adapt autonomously is what makes AI so powerful for future-proofing logistics.

Personalized Delivery Options and Customer Experience

In 2025, customer experience extends far beyond the product itself to encompass the entire delivery journey. Offering a range of personalized delivery options – such as specific time slots, alternative pick-up locations, or carbon-neutral delivery choices – empowers customers and enhances their satisfaction.

This requires a flexible and adaptable fulfillment system that can accommodate diverse customer preferences without incurring prohibitive costs. Transparency in tracking and proactive communication about delivery status are also critical components of a superior customer experience.

As e-commerce continues its rapid expansion, the link between efficient, customer-centric shipping and overall business success will only strengthen. Businesses that prioritize continuous improvement and innovation in their fulfillment strategies will be best equipped to thrive in the competitive market of 2025 and beyond.

| Key Area | Brief Description |

|---|---|

| 📦 Smart Packaging | Optimize package size and material to reduce dimensional weight costs. |

| 🚀 Faster Delivery | Implement micro-fulfillment centers and warehouse automation. |

| ⚙️ Tech Integration | Leverage OMS, AI, and predictive analytics for seamless logistics. |

| ♻️ Green Logistics | Adopt eco-friendly packaging and carbon offset programs. |

Frequently Asked Questions About E-commerce Shipping and Fulfillment in 2025

▼

AI significantly impacts shipping costs by optimizing routes, predicting demand, and minimizing errors. It helps in selecting the most cost-effective carriers, reducing fuel consumption through efficient routing, and ensuring inventory is placed optimally to lower last-mile delivery expenses. This leads to overall operational savings and improved efficiency in logistics.

▼

Micro-fulfillment centers (MFCs) are typically small, automated warehouses located closer to urban populations. Their main purpose is to reduce delivery times significantly by storing inventory nearer to end customers. This enables quicker order processing, often facilitating same-day or next-day delivery, and can also lead to reduced last-mile shipping costs due to shorter distances.

▼

To negotiate better rates, understand your shipping volume and patterns, consolidate shipments, and consider diversifying across multiple carriers. Present carriers with your detailed shipping data, highlight your potential growth, and be prepared to commit to certain volumes for better discounts. Leverage competition among carriers to secure more favorable terms for your business.

▼

Sustainable shipping is crucial for e-commerce due to growing consumer demand for eco-friendly practices and increasing regulatory pressures. It enhances brand reputation, attracts environmentally conscious customers, and can lead to long-term cost savings through optimized energy use and recyclable materials. Embracing sustainability showcases corporate responsibility and secures future-proof operations.

▼

An OMS is central to efficient e-commerce fulfillment, acting as a hub for all order-related processes. It manages orders from multiple channels, integrates with inventory and shipping systems, and ensures accurate, timely processing. A robust OMS minimizes manual errors, optimizes order routing, and provides real-time visibility, leading to faster fulfillment and improved customer satisfaction.

Conclusion

Optimizing e-commerce shipping and fulfillment in 2025 requires a proactive, strategic approach focused on cutting costs and improving delivery times. By embracing technological advancements like AI and predictive analytics, refining packaging and carrier negotiations, and adopting sustainable practices, businesses can not only meet evolving customer expectations but also achieve a significant competitive advantage. The future of e-commerce lies in intelligent, efficient, and customer-centric logistics, transforming challenges into opportunities for growth and loyalty.