E-commerce Inventory Management: Reduce Stockouts and Overstocking with These Tips

Effective e-commerce inventory management is crucial for online businesses to optimize their operations, ensuring products are available when customers want them while preventing the financial drain of excessive stock, ultimately leading to enhanced profitability and customer satisfaction.

In the dynamic world of online retail, balancing supply with demand is a constant challenge. For any e-commerce business, efficient e-commerce inventory management: reduce stockouts and overstocking with these tips is not just a best practice; it’s a fundamental pillar for sustainable growth and profitability. Without a robust system, businesses risk frustrating customers with out-of-stock items or bleeding cash by holding too much unsold inventory.

Understanding the Core Challenges of E-commerce Inventory

Managing inventory in e-commerce presents a unique set of hurdles compared to traditional retail. The rapid pace of online sales, global supply chains, and the expectation of immediate fulfillment mean that businesses must be agile and precise. Two primary issues consistently plague online retailers: stockouts and overstocking.

Stockouts, or running out of popular products, lead directly to lost sales, frustrated customers, and damaged brand reputation. Imagine a customer ready to make a purchase, only to find the item unavailable. This isn’t just a missed sale for today; it could mean a lost customer for good. Conversely, overstocking ties up valuable capital, incurs storage costs, and increases the risk of obsolescence, especially for seasonal or trend-driven products. Achieving a balance between these two extremes is the delicate art of effective inventory management.

The Impact of Stockouts and Overstocking

Each of these inventory woes carries significant repercussions:

- Lost Revenue: Stockouts mean immediate lost sales and potential future sales if customers switch to competitors.

- Increased Costs: Overstocking leads to higher storage fees, insurance costs, and the risk of markdowns or write-offs for unsold goods.

- Customer Dissatisfaction: Repeated stockouts deter customers, while a lack of new products due to overstocking can make a store seem stale.

- Operational Inefficiencies: Poor inventory data can lead to inefficient warehouse operations, mispicks, and delays in shipping.

Understanding these challenges is the first step toward implementing strategies that can mitigate their impact and move your e-commerce operation towards greater efficiency and profitability. It’s about recognizing that inventory isn’t just goods on a shelf; it’s a living, breathing part of your business’s financial and operational health.

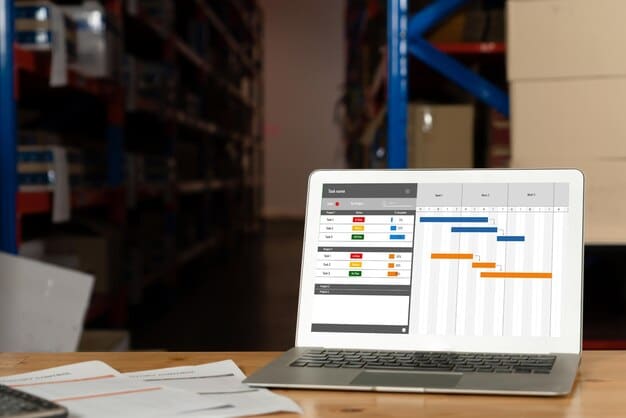

Leveraging Technology for Smart Inventory Control

In today’s competitive e-commerce landscape, manual inventory management is no longer a viable option for businesses looking to scale. The sheer volume of transactions, product variations, and supply chain complexities demand advanced technological solutions. Inventory management software (IMS) or enterprise resource planning (ERP) systems are becoming indispensable tools for online retailers.

These systems offer real-time visibility into stock levels across all sales channels, automate numerous processes, and provide data-driven insights essential for informed decision-making. From tracking every SKU to managing returns and predicting future demand, technology transforms inventory from a static asset into a dynamic, responsive element of your business model.

Key Features of Modern Inventory Software

A robust inventory management system should offer a suite of features designed to address the specific needs of e-commerce:

- Real-time Tracking: Instant updates on stock levels, allowing for accurate fulfillment and preventing overselling.

- Automated Reordering: Setting reorder points and quantities to automatically generate purchase orders when stock runs low.

- Multi-channel Synchronization: Unifying inventory across your website, marketplaces (like Amazon or eBay), and any physical stores.

- Reporting and Analytics: Providing detailed reports on sales trends, inventory turnover, and profitability by product.

- Forecasting Tools: Utilizing historical data and algorithms to predict future demand and optimize stock levels.

Furthermore, the integration capabilities of these platforms are crucial. An IMS that seamlessly connects with your e-commerce platform, shipping carriers, and accounting software creates a unified operational ecosystem, eliminating data silos and reducing manual efforts. This interconnectedness allows for a smoother flow of information and more accurate insights, making your inventory management truly smart.

Mastering Demand Forecasting and Analytics

At the heart of effective inventory management lies accurate demand forecasting. It’s the ability to predict future customer demand based on historical sales data, market trends, seasonality, and promotional activities. Without reliable forecasts, businesses are essentially guessing, leading to either stockouts or overstocking. This predictive capability transforms inventory management from a reactive process into a proactive strategy.

Advanced analytics tools play a critical role here, as they can process vast amounts of data and identify patterns that would be impossible for human analysis to detect. These insights allow businesses to optimize stock levels, plan purchasing more efficiently, and even anticipate shifts in customer preferences, giving them a significant competitive edge.

Data Points for Precise Forecasting

To build accurate forecasts, consider analyzing the following data points:

- Historical Sales Data: Look at past sales trends, identifying peak seasons, slow periods, and consistent sellers.

- Market Trends: Stay informed about broader industry changes, emerging products, and competitor activities.

- Promotional Activities: Anticipate increased demand during sales, marketing campaigns, or holiday promotions.

- External Factors: Consider economic indicators, social trends, and unexpected events that might impact consumer behavior.

Beyond simply predicting demand, analytics also help in identifying slow-moving or stagnant inventory. By analyzing inventory turnover rates and sales velocity, businesses can make informed decisions about product lifecycle management, such as implementing discounts to move old stock or discontinuing underperforming items. This continuous analytical feedback loop ensures that inventory remains dynamic and aligned with market realities, rather than static and prone to becoming a liability.

Implementing Efficient Ordering and Replenishment Strategies

Once you have a clear understanding of your demand, the next crucial step is to implement efficient ordering and replenishment strategies. This involves determining when to reorder stock and how much to order to maintain optimal inventory levels. Poor ordering practices can quickly negate the benefits of accurate forecasting, leading to wasted capital or missed sales opportunities.

The goal is to strike a balance between carrying enough stock to meet demand without holding excess inventory that incurs unnecessary costs. This often involves a blend of fixed-point reordering, where orders are placed when stock hits a predetermined level, and fixed-interval reordering, where orders are placed at regular scheduled times, adjusting quantities based on current demand.

Key Ordering and Replenishment Principles

Consider these principles for optimizing your purchasing process:

- Set Reorder Points: Establish minimum stock levels that trigger a new order, accounting for lead times.

- Calculate Economic Order Quantity (EOQ): Determine the ideal order size to minimize overall inventory costs (holding costs + ordering costs).

- Supplier Relationship Management: Build strong relationships with reliable suppliers to ensure consistent quality and timely deliveries.

- Safety Stock: Maintain a buffer of extra inventory to account for unexpected demand spikes or supply chain disruptions.

Implementing these strategies requires continuous monitoring and adjustment. What works one quarter might not work the next, as market conditions, supplier lead times, and customer behaviors evolve. A flexible and adaptive approach, supported by real-time data from your inventory management system, will ensure your ordering process remains agile and responsive to the needs of your e-commerce business. This iterative process of review and refinement ensures that your replenishment strategies are always aligned with both your operational capabilities and market demands.

Optimizing Warehouse Organization and Layout

An often-overlooked aspect of e-commerce inventory management is the physical organization of your warehouse or storage facility. A well-organized and optimized warehouse layout can significantly reduce picking times, minimize errors, and improve overall operational efficiency. Conversely, a chaotic storage space can lead to delays, lost products, and increased labor costs, even if your digital inventory records are perfect.

The flow of goods from receiving to shipping should be intuitive and logical, ensuring that products are easily accessible and that movement within the warehouse is minimized. This involves strategic placement of fast-moving items, efficient shelving, and clear labeling systems, all contributing to a smoother fulfillment process.

Strategies for Warehouse Optimization

Consider these strategies to enhance your warehouse efficiency:

- Zone Picking: Divide your warehouse into zones, with pickers assigned to specific areas, reducing travel time within the facility.

- Slotting Optimization: Strategically place products based on their sales velocity, size, and weight to minimize picking paths.

- Bin Location System: Implement a clear and consistent labeling system for every storage location, making products easy to find.

- Regular Audits: Periodically review your warehouse layout and practices to identify bottlenecks and areas for improvement.

Furthermore, investing in proper equipment, such as ergonomic shelving, efficient forklifts, or even automated guided vehicles (AGVs) for larger operations, can further boost productivity. The goal isn’t just to store products; it’s to create an environment where products can be moved, picked, and packed with maximum speed and accuracy. A meticulously organized warehouse is a silent partner in your fulfillment success, directly impacting your ability to deliver on customer expectations and maintain profitability.

Proactive Mitigation of Inventory Risks

Beyond managing the day-to-day flow of goods, proactive inventory management also involves anticipating and mitigating various risks that can disrupt your supply chain or impact your stock value. These risks can range from natural disasters and geopolitical events to supplier failures, product damage, or even theft. While not all risks can be entirely avoided, having contingency plans in place can significantly minimize their impact.

Risk mitigation in inventory isn’t just about protecting your current stock; it’s about safeguarding your entire business continuity. This involves diversification, robust insurance, and the implementation of internal controls to prevent losses and ensure operational resilience in the face of unforeseen challenges.

Strategies for Risk Mitigation

To protect your inventory and operations, consider these strategies:

- Supplier Diversification: Don’t rely on a single supplier for critical products; have alternative sources in case of disruptions.

- Insurance Coverage: Ensure your inventory is adequately insured against damage, loss, or theft during storage and transit.

- Quality Control: Implement rigorous quality checks upon receiving goods to prevent defective or damaged products from entering your saleable inventory.

- Security Measures: Install surveillance, access controls, and regular inventory counts to deter theft and accurately track discrepancies.

- Regular Backups: Ensure your digital inventory data is regularly backed up to prevent loss from system failures or cyber incidents.

Building a resilient inventory system means thinking beyond the immediate transaction. It involves a holistic view of your supply chain and a commitment to proactive planning. By identifying potential vulnerabilities and developing strategies to address them, businesses can not only reduce financial losses but also build stronger, more reliable operations that are better prepared to navigate the unpredictable nature of global commerce. This forward-looking approach to inventory management transforms potential pitfalls into opportunities for resilience.

Ensuring your e-commerce business thrives in a competitive market requires more than just great products; it demands meticulous attention to every operational detail. By consistently applying smart inventory management principles—from accurate forecasting and efficient ordering to optimized warehouse organization and proactive risk mitigation—businesses can unlock significant benefits. This comprehensive approach helps reduce the costly issues of stockouts and overstocking, freeing up capital, improving customer satisfaction, and ultimately driving sustainable growth.

| Key Point | Brief Description |

|---|---|

| 📊 Demand Forecasting | Predict future demand using historical data, trends, and promotions to avoid stockouts or overstocking. |

| 💻 Tech Adoption | Utilize inventory management software for real-time tracking, automation, and multi-channel synchronization. |

| 📦 Optimized Workflow | Improve warehouse layout and picking strategies to enhance efficiency and reduce operational costs. |

| 🛡️ Risk Mitigation | Diversify suppliers, ensure insurance, and implement quality checks to protect against supply chain disruptions. |

Frequently Asked Questions About E-commerce Inventory Management

▼

The primary goal is to maintain optimal stock levels to meet customer demand without incurring excessive holding costs or experiencing stockouts. This balance ensures profitability, customer satisfaction, and efficient operations by preventing capital from being tied up in unsold goods and avoiding missed sales opportunities due to unavailable items.

▼

Demand forecasting predicts future customer needs by analyzing historical data, market trends, and seasonal patterns. By accurately anticipating demand, businesses can order the right quantity of products at the right time, thereby preventing stockouts of popular items and avoiding overstocking slow-moving inventory, which ties up capital.

▼

Technology, specifically inventory management software, provides real-time visibility into stock levels, automates reordering processes, and offers data analytics for informed decision-making. It integrates with e-commerce platforms and shipping carriers, significantly enhancing efficiency, reducing manual errors, and enabling multi-channel synchronization for accurate stock counts across all sales outlets.

▼

The main risks include significant financial losses from lost sales due to stockouts, increased carrying costs from overstocking, and a damaged brand reputation due to customer dissatisfaction. Additionally, it can lead to operational inefficiencies, wasted warehouse space, and the risk of product obsolescence or spoilage, impacting profitability.

▼

Optimizing your warehouse involves strategic layout planning, such as implementing zone picking or slotting optimization to minimize picking paths. Using a clear bin location system, conducting regular audits, and investing in appropriate equipment also improve efficiency. These measures ensure products are easily accessible, reducing picking times and minimizing errors.

Conclusion

Effective e-commerce inventory management is a cornerstone of success for any online business. By embracing robust strategies, leveraging advanced technology, and adopting a proactive approach to risk, businesses can transform their inventory from a complex challenge into a powerful asset. Mastering these aspects will not only reduce costly stockouts and overstocking but also enhance operational efficiency, improve customer satisfaction, and ultimately drive sustainable growth in the competitive digital marketplace.